Honda Snow Blower Model Number Decoding:

Example: HSS1332ACTD/A

HS = Honda Snow Blower

S = Small Frame (some say Steering)

13 = Nominal Gross HP (5=GX140, 6=GX160, 7=GX200, 8=GX240, 9=GX270, 11=GX340, 13=GX390)

32 = Clearing Width (inches = 22, 24, 28, 32, 36 or centimeters = 55, 60, 70, 80, 90)

A = Made at Honda's plant in Swepsonville, North Carolina, USA (Often omitted - This is the "A" on the chute motor cover of all 2015+ HSS machines)

C = Canada spec model (USA spec model would have an "A" here, "E" for Euro - follows drive type on HS models)

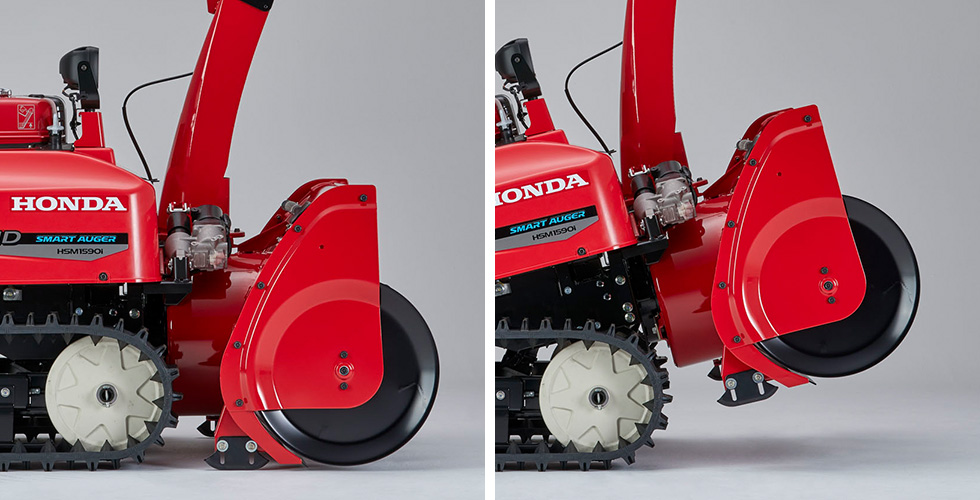

T = Track drive (or W for wheel drive)

D = 12V D.C. on-board battery Electric Start

S = 120V Electric Start

/A = Revision

Kx = Revision (HS)

Honda's Consistent method of rating engine power

Towards a consistent method of rating engine power across all product lines.

As the world's largest engine manufacturer, Honda has decided to apply a consistent method of rating engine power across all product lines; Auto, Motorcycle and Power Equipment; following the notion of ‘Net' power, rather than ‘Gross'. We would like to announce to you that Honda will be the first engine manufacturer to rate all general purpose engines at Net kW (Horsepower) in accordance with the Society of Automotive Engineers (SAE) J1349 test procedure. At the same timing we will also change the way of indicating the torque values (also measured with the ‘Net' setup), fuel consumption (change from g/kW.hr to L/hr) and fuel tank capacity.

Effective for the 2007 model year, Honda kW (HP) specifications for all general purpose engines will be calculated pursuant to SAE J1349 for net power ratings. These net calculations represent changes in the method in which engine power is measured and will result in a change from 2006 published kW (HP) values for individual engine models. Net kW (HP) is calculated with the air cleaner and muffler attached. Gross power calculations are generated without those features. It is important to note that our engines and their power output will be unchanged.

Honda has adopted SAE net power calculations in part as a convenience for the many end users that are buying a product ‘Powered by Honda'. By standardizing our worldwide engine power ratings in accordance with SAE J1349, everybody in the market will enjoy a consistent value for each of our distinct engine models regardless of country of manufacture or sale. The use of this standard will also allow our customers to more easily determine the suitability of an engine for a particular application.

In 2007, Honda will begin to transition all Honda general purpose engines documentation (catalogues, websites, owner's manuals, etc.) to ultimately identify these SAE J1349 ratings where kW (HP) and related values (like torque) are provided.

Honda has always been committed to providing our business partners and customers with the highest quality, most reliable and efficient general purpose engines that we can produce. Since no mechanical changes will be made to our general purpose engine line-up in relation to the SAE J1349 ratings, you and your customers can expect the identical levels of power output, quality, durability and performance that you have come to expect from our engine products.

Attached table of kW according to SAEJ1349

The power rating of the engine indicated in this table is the net power output tested on a production engine for the engine model and measured in accordance with SAE J1349 at a specified rpm. Mass production engines may vary from this value. Actual power output for the engine installed in the final machine will vary depending on numerous factors, including the operating speed of the engine in application, environmental conditions, maintenance, and other variables.

Example: HSS1332ACTD/A

HS = Honda Snow Blower

S = Small Frame (some say Steering)

13 = Nominal Gross HP (5=GX140, 6=GX160, 7=GX200, 8=GX240, 9=GX270, 11=GX340, 13=GX390)

32 = Clearing Width (inches = 22, 24, 28, 32, 36 or centimeters = 55, 60, 70, 80, 90)

A = Made at Honda's plant in Swepsonville, North Carolina, USA (Often omitted - This is the "A" on the chute motor cover of all 2015+ HSS machines)

C = Canada spec model (USA spec model would have an "A" here, "E" for Euro - follows drive type on HS models)

T = Track drive (or W for wheel drive)

D = 12V D.C. on-board battery Electric Start

S = 120V Electric Start

/A = Revision

Kx = Revision (HS)

Honda's Consistent method of rating engine power

Towards a consistent method of rating engine power across all product lines.

As the world's largest engine manufacturer, Honda has decided to apply a consistent method of rating engine power across all product lines; Auto, Motorcycle and Power Equipment; following the notion of ‘Net' power, rather than ‘Gross'. We would like to announce to you that Honda will be the first engine manufacturer to rate all general purpose engines at Net kW (Horsepower) in accordance with the Society of Automotive Engineers (SAE) J1349 test procedure. At the same timing we will also change the way of indicating the torque values (also measured with the ‘Net' setup), fuel consumption (change from g/kW.hr to L/hr) and fuel tank capacity.

Effective for the 2007 model year, Honda kW (HP) specifications for all general purpose engines will be calculated pursuant to SAE J1349 for net power ratings. These net calculations represent changes in the method in which engine power is measured and will result in a change from 2006 published kW (HP) values for individual engine models. Net kW (HP) is calculated with the air cleaner and muffler attached. Gross power calculations are generated without those features. It is important to note that our engines and their power output will be unchanged.

Honda has adopted SAE net power calculations in part as a convenience for the many end users that are buying a product ‘Powered by Honda'. By standardizing our worldwide engine power ratings in accordance with SAE J1349, everybody in the market will enjoy a consistent value for each of our distinct engine models regardless of country of manufacture or sale. The use of this standard will also allow our customers to more easily determine the suitability of an engine for a particular application.

In 2007, Honda will begin to transition all Honda general purpose engines documentation (catalogues, websites, owner's manuals, etc.) to ultimately identify these SAE J1349 ratings where kW (HP) and related values (like torque) are provided.

Honda has always been committed to providing our business partners and customers with the highest quality, most reliable and efficient general purpose engines that we can produce. Since no mechanical changes will be made to our general purpose engine line-up in relation to the SAE J1349 ratings, you and your customers can expect the identical levels of power output, quality, durability and performance that you have come to expect from our engine products.

Attached table of kW according to SAEJ1349

The power rating of the engine indicated in this table is the net power output tested on a production engine for the engine model and measured in accordance with SAE J1349 at a specified rpm. Mass production engines may vary from this value. Actual power output for the engine installed in the final machine will vary depending on numerous factors, including the operating speed of the engine in application, environmental conditions, maintenance, and other variables.

| Net Power | |||

| Model | kW | HP | rpm |

| GX100 | 2,1 | 2,8 | 3.600 |

| GX120 | 2,6 | 3,5 | 3.600 |

| GX160 | 3,6 | 4,8 | 3.600 |

| GX200 | 4,1 | 5,5 | 3.600 |

| GC160 | 3,4 | 4,6 | 3.600 |

| GC190 | 3,9 | 5,2 | 3.600 |

| GX240 | 5,9 | 7,9 | 3.600 |

| GX270 | 6,3 | 8,4 | 3.600 |

| GX340 | 8 | 10,7 | 3.600 |

| GX390 | 8,7 | 11,7 | 3.600 |

| GX240i | 5,9 | 7,9 | 3.600 |

| GX270i | 6,3 | 8,4 | 3.600 |

| GX340i | 8 | 10,7 | 3.600 |

| GX390i | 8,7 | 11,7 | 3.600 |

| GX630 | 15,5 | 20,8 | 3.600 |

| GX660 | 16 | 21,5 | 3.600 |

| GX690 | 16,5 | 22,1 | 3.600 |

| GCV135 | 2,6 | 3,5 | 3.600 |

| GCV160 | 3,3 | 4,4 | 3.600 |

| GCV190 | 3,8 | 5,1 | 3.600 |

| GSV190 | 3,8 | 5,1 | 3.600 |

| GXV160 | 3,2 | 4,3 | 3.600 |

| GXV340 | 6,6 | 8,9 | 3.600 |

| GXV390 | 7,6 | 10,2 | 3.600 |

| GXV630 | 15,5 | 20,8 | 3.600 |

| GXV660 | 16 | 21,5 | 3.600 |

| GXV690 | 16,5 | 22,1 | 3.600 |

| GX25 | 0,72 | 1 | 7.000 |

| GX35 | 1 | 1,3 | 7.000 |

| GXH50 | 1,6 | 2,1 | 7.000 |

| GXV50 | 1,6 | 2,1 | 7.000 |

| GXV57 | 1,5 | 2 | 4.800 |